How Sake is made?

Sake is an alcoholic beverage made from rice.

Usually, alcoholic beverages are made by producing alcohol by fermenting raw materials with the help of microorganisms. This method is used to make Sake, Wine and Beer.

Sake is not a distilled spirit. Distilled spirits include be shochu, brandy, whiskey, vodka,gin etc.

During the fermentation process, the yeast, which is a microorganism, consumes sugar and produces alcohol and carbon dioxide.

Of the brewed liquors, the simplest form is to make the liquor by fermenting the sugar contained in the raw materials from the beginning, so it is thought that this was the first type of liquor that mankind first made. Wine is typical of this type.

This type of fermentation is called simple fermentation because it only needs to be fermented simple way.

On the other hand, sake is made from cereal grains, so there is no sugar, then alcoholic fermentation is not possible. Therefore,another ingredient is needed. This is called Koji Mold.

Koji Mold is added to the rice and it breaks down the starch of rice into sugars. This is called saccharification.

Yeasts eat the resulting sugar and produce alcohol and carbon dioxide.

This way of fermenting alcohol through two steps is called double fermentation.

In the case of sake, in particular, saccharification and fermentation proceed simultaneously by the koji ‘s working, and this is called parallel double fermentation, which is one of the characteristics of sake.

For reference, beer is called single fermentation because malt is used for saccharification first, followed by alcohol fermentation.

In Europe and America, saccharification is performed using malt as described above, whereas in the East including Japan, Koji Mold, a microorganism, is used for saccharification.

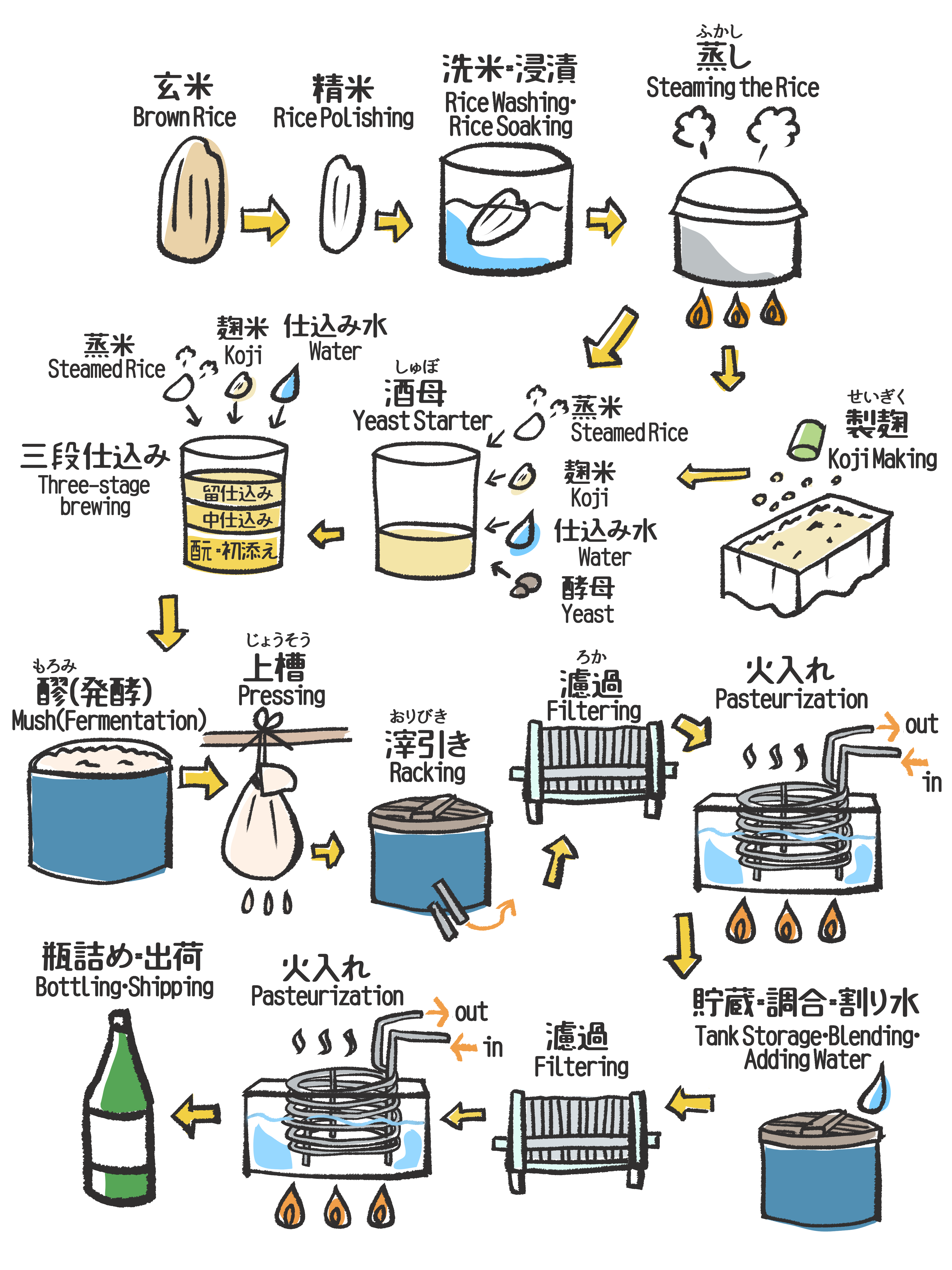

Sake brewing process

Rice Polishing

Sake is made from polished rice, because brown rice contains a lot of proteins and lipids near the surface which make Sake taste rough so these are removed from rice by polishing for good Sake.

Nomally, Seimai-buai (pollishing ratio) is 70% or less. For example,It is 60% or less for Ginjo-She, 50% or less for Dai-ginjo-shu. They are more smooth and more refined.

Seimai-buai (Polishing ratio)

Seimai-buai (the polishing ratio) is calculated as follows :

weight of rice after polishing / weight of Brown rice × 100 = Seimaibuai (%)

Raw material processing

After polishing the rice, wash it and remove the rice bran on the surface, then let the water drain.

The process of soaking water is very important because it greatly affects the later making of koji.

The rice is steamed in a Koshiki (steaming pot) and it is cooled, it is carried into Koji-Muro (Koji making room).

Koji making process

The steamed rice is spread on the rack. Then koji mould is sprinkled over it, and it is mixed well .

After half a day the steamed rice is removed, and it is divided in some koji-boxes .Then temperature and humidity are controlled in Koji-Muro, and the koji mold is grown to a target state.

Yeast Starter making

The first process is to make the starter that koji and water, lactic acid, yeast, are added to the steamed rice, and the yeast had cultured in large quantities. The so-called Shubo(Yeast Starter) is a large amount of yeast cultured in this way. In Japanese, it is the mother of sake as the letters indicate.

The reason why lactic acid is added when making sake, it is to kill bacteria except yeast, by making the environment strongly acidic.

Yeast bacteria have a strong tolerance to acidity, so they can increase in liquors without being affected by various bacteria in this environment.

What I explained above is the method of quick brewing that is now mainstream. In addition, there is Kimoto-method, which is a traditional method of culturing by incorporating natural lactic acid bacteria instead of adding lactic acid.

Brewing

In the next step more steamed rice, Koji and waters are added to the yeast starter to increase the amount. This process is called Shikomi (preparation for fermantation).

If all raw materials that using amount of brewing are charged at once, the acidity will decrease and the risk of miscellaneous bacteria growth will increase, and the amount of sugar content will increase then the ability of the yeast will weaken, so it would be impossible to ferment sufficiently. Therefore the method of three-stage brewing, which increases the amount in three stage for four days, has become the mainstream.

After the third stage is completed, fermantation is usually completed in 20 days, but it takes 30 to 40 days for special quality sake such as Ginjo and Daiginjo, so-called Moromi (mash of sake).

Pressing

When the fermantation is finished, Moromi is pressed by filter. This process is called Joso(Pressing).

Generally, after pressing, it has be pasteurized. It is then stored in a tank and pasteurized again before bottling.

The one that is not pasteurized is called “Nama-Sake”. In addition, there are “Nama-dume-shu” or “Nama-chozo-shu” that are only pasteurized once.

Shipment

Some sakes are shipped immediately after pressing, others are shipped after long time storage. Therefore, the date of manufacture on the sake label indicates when it was bottled, not the day it was pressing.